Love Made Visible

How America's Oldest Jeweler Embraces Innovation To Make The Old Ways New Again.

There is no more enduring symbol of love than the diamond engagement ring. And in the United States, there is no more enduring fine jeweler than Bixlers.

Twice in its storied history, Bixlers has been recognized by none other than Tiffany & Co. praising Bixlers as ““not only the oldest but one of the finest jewelers in America.”

Bixlers has handcrafted engagement rings for centuries. The secret to their longevity: don’t just embrace change. Inspire it. Founded by a master clockmaker, Bixlers’ innovative approach applies the intricacy and precision of fine timepiece making to fine jewelry making.

Each stage of production is handled by an expert in a specific discipline with 1000 years of combined jewelry-making experience.

Where many fine jewelers moved manufacturing overseas, Bixlers moved its manufacturing to Montreal, Canada. Powered by 99% renewable energy and utilizing 100% repurposed precious metals and ethically sourced gemstones, the Bixlers atelier is certified sustainable by the Responsible Jewellery Council.

And from concept to design, handcraft to final ship, it all happens under one roof.

The Journey Of A Bixlers Engagement Ring

First, We Dream Together

Conception + Design

Conception + Design

Conception + Design

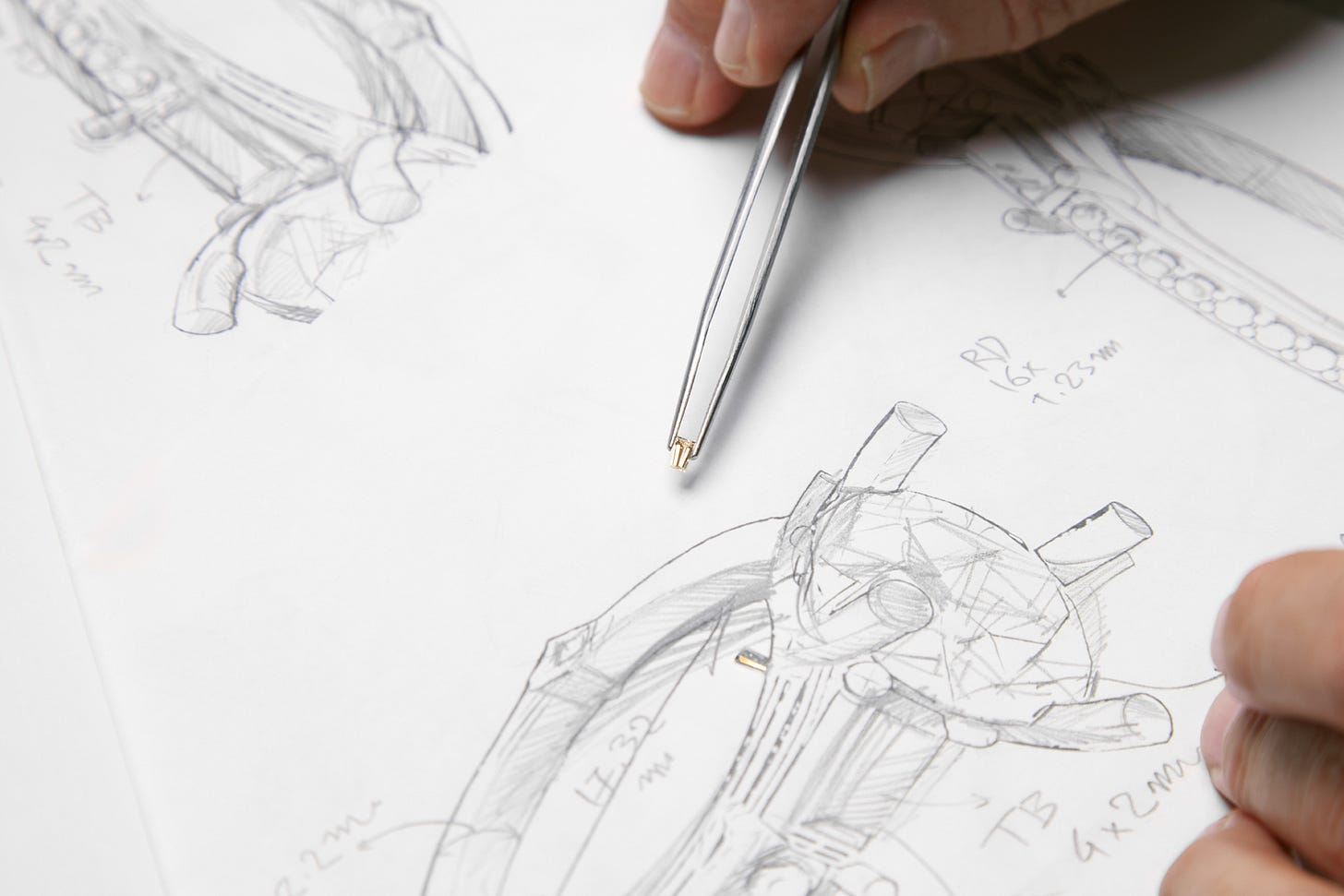

The exclusivity of a Bixlers engagement ring lies in the time and care it takes to craft it. Bixlers is 100% independently owned and operated, offering customers direct access to its atelier. CEO, and visionary, Perry Sporn, dreams up each design with the atelier’s in-house team of designers and engineers. Customers are also encouraged to provide their sketches and design ideas. “If you can dream it, we can do it.”- -CEO, Perry Sporn

Extraordinarily Exacting

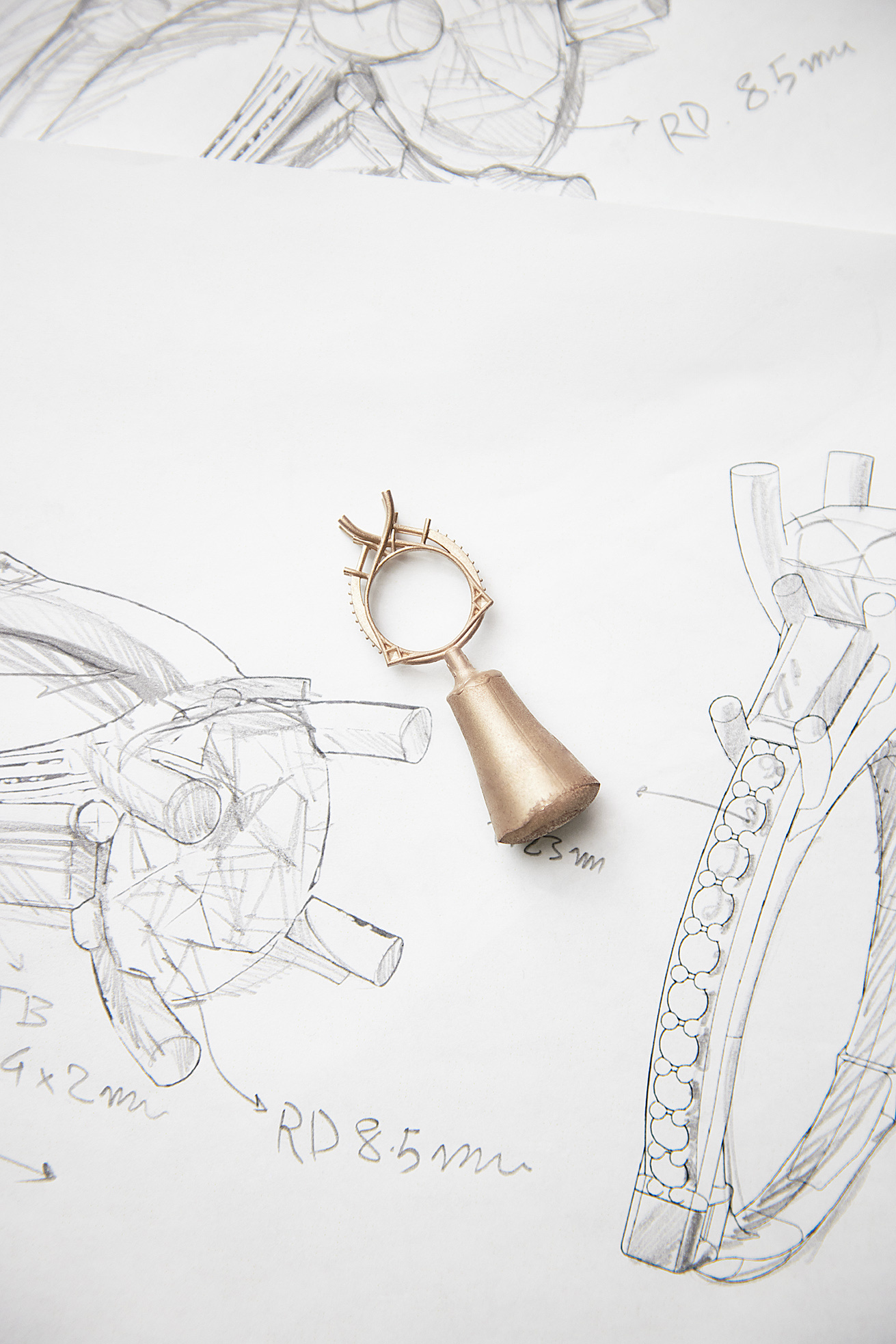

CAD + 3D Printing

Using the latest in engineering software and 3D printing technology, models of each piece are created to be architecturally perfect, each facet designed down to the width of a human hair. Six Sigma quality control measures are in place at each stage of production. Bixlers’ designers provide intricate clockwork for the craftspeople to work with. If any flaw exists in the design, it will have repercussions on the manufacturing floor. There is no room for error.

A Rare Alchemy

Gold Smelting

Gold Smelting

Gold Smelting

Solid repurposed precious metal is melted to a liquid at 1000 degrees in less than 2 minutes. Virtually all power used in the Bixlers atelier comes from renewable energy. In an energy-intensive process, this achievement cannot be overstated.

From Seed To Tree

Casting Process

Yield From Casting Process

Yield From Casting Process

Liquid gold is channeled into the complex mazework of the model, designed to eliminate any pockets of space to reduce porosity and increase strength. The casting plaster is power-washed away to reveal a “tree” of precious metal. If any flaw is found, the piece is melted down and recycled. The ring is then plucked from the tree in a process called “de-spruing”. Each tree is de-sprued by hand to ensure zero damage.

Shine

Pre-Polishing

Pre-Polishing

Pre-Polishing

After de-spruing, the ring is pre-polished by hand and under microscope.

Gemstone Sourcing

Treasure Hunting

Gemstone Sourcing - a Bixlers sawn diamond

Gemstone Sourcing - a Bixlers sawn diamond

For engagement rings and custom pieces, Perry personally sources gemstones from all over the world to ensure each customer receives the jewel of their dreams. For the center stone of an engagement ring, Bixlers uses “sawn” diamonds as opposed to laser-cut. “Sawn” diamonds are renowned for their complex crystal structure. Greater complexity means greater luster.

Love Guides The Hand

Stone Setting

Stone Setting

Stone Setting

Each diamond is set by hand into the prongs that cradle the diamonds. Each prong is then molded around each jewel by hand. The prongs and band are cast as one solid piece of gold to increase durability. “Built to last isn’t just a design feature, it’s part of our legacy.” – CEO, Perry Sporn

Shimmer

Polishing

Final Polishing Under Microscopic Lens

Final Polishing Under Microscopic Lens

The final polishing smooths the piece to a mirror finish, achieving perfect symmetry and flawless-grade shimmer.

The Difference Is All The Difference

Delivery

Three Stone Baguette Engagement Ring in 14K Gold, handcrafted by Bixlers

Three Stone Baguette Engagement Ring in 14K Gold, handcrafted by Bixlers

Once complete, the engagement ring is shipped directly from the atelier to the customer. When time has proven a factor, Perry has personally delivered engagement rings and wedding bands to customers in time for their proposal or wedding day. “Our devotion to our craft begins with our devotion to our customer.” -- CEO, Perry Sporn.

Behind each piece is a team of expert jewelry artisans handcrafting sustainably made treasures with the intricacy and precision of a timepiece. And though that difference may go unnoticed, hold a Bixlers piece up to any other, and the difference is clear.

Discover the Bixlers difference at Bixlers.com